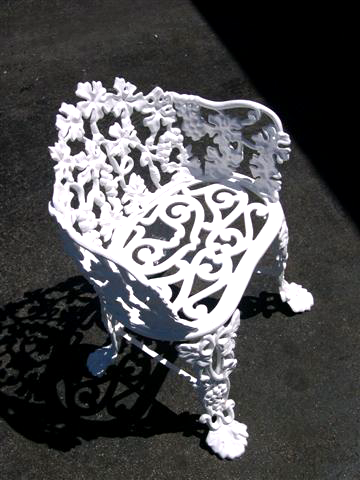

Powder coating is a coating applied as a free-flowing, dry powder. The main difference between a conventional liquid paint and powder coating is the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form. The coating is typically applied electrostatically then cured under heat in an oven to allow it to flow and form a skin. The powder may be a thermoplastic or a thermoset polymer. It is used to create a hard finish up to 10 times tougher than conventional paint. Powder coating is primarily used for the coating of metals.

What are the advantages?

*Superior durability, up to 10 times more durable than traditional wet paint.

* Powder coatings emit zero or near zero volatile organic compounds (VOC).

* Powder coating can a produce much thicker coating than conventional liquid coatings, without running or sagging.

* Powder coating overspray can be recycled making it possible to achieve nearly 100% efficiently of use.

* Powder coating production lines produce less hazardous waste than conventional liquid coatings.

What is powder coating?